Position:Home> Product

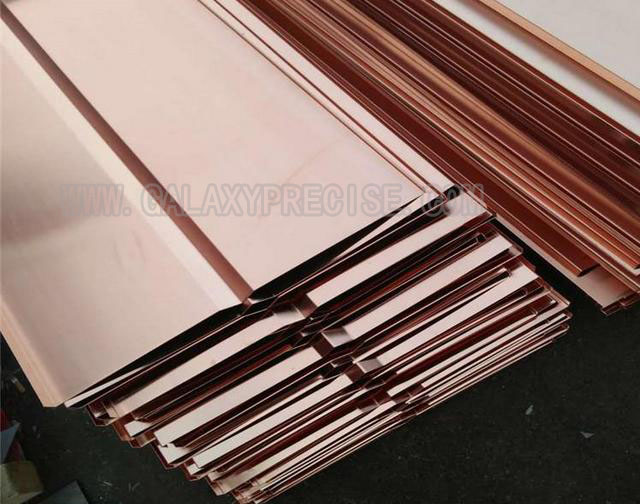

High-voltage Current-limiting Fuse Part

| Material | Caps:brass with tin plating Knife-shaped contact:C11000 copper |

| Features | 1.firmly and seamlessly welded; 2.The solder is full with pore-free and no tin on the edge; 3. Low welding resistance , and the parts after welding are not deformed; |

| Specification | No Standard |

| Certification | IATF 16949 & ISO9001 |

| Application | Bolted fast acting fuse is a very common protector which is used to protect generator, transformer and other important equipment. |

Product Information

A. Firmly and seamlessly welded;

B. The solder is full with pore-free and no tin on the edge;

C. Low welding resistance , and the parts after welding are not deformed.

Our welding component is used in bolted fuses for electrical vehicles. Bolt-connected fuses for new energy vehicles are suitable for the road vehicle industry. They can be used as electric vehicle drive power systems, power conversion systems, energy storage and power batteries, energy storage capacitors, inverter controllers, chargers, wires and other automotive devices. Short circuit, overload and backup protection of the equipment.

A.The cap is made of high quality brass belt, which has good plasticity , high strength and good cutting performance.It is easy to weld and very stable to corrosion.

B.The knife-shaped contact is made of high-quality red copper belt with high purity, fine structure and extremely low oxygen content.The welding component produced is pore-free and performs excellent electrical conductivity. It has good electrical, thermal, corrosion and processing properties, can be welded and brazed. The welding component for fuse performs good thermal conductivity, processability, ductility, corrosion resistance and weather resistance.

Our company is located in the auto parts industry park in Xiamen city,fujian Province,China.It covers an area of about 5000 square meter.There are stamping division,welding division,research & development department, new energy division,purchasing department,quality department,material control department ,domestic department and international department.

1) Punching: Professional and independent stamping die design team, and has more than 30 punching machine production equipment, from 10T to 110T, respectively applicable to the production of different specifications of products.The main features of these equipment are large capacity, low power consumption, stamping times per day up to 2 million times.

2) Pickling: It is a method to clean the metal surface by removing the oxide and rust on the steel surface with acid solution.Common solutions include sulfuric acid, hydrochloric acid, phosphoric acid, nitric acid, chromic acid, hydrofluoric acid and mixed acid.The most commonly used are sulfuric acid and hydrochloric acid.

3) Welding: Adopt automatic printing machine and automatic welding equipment, high welding efficiency, good stability, seamless welding, beautiful appearance.

4) Grinding: The grinding machine is a grinding machine that USES grinding tools coated with or embedded with abrasive to grind the surface of the workpiece.

5) Riveting: Electric small punch riveting, electric punch has the characteristics of light weight, high production efficiency, simple operation, low noise, high precision, machining parts size is accurate, punching and cutting surface is bright and clean, especially suitable for high-rise buildings and workshop operation.The application scope is extremely wide, may to the black and the nonferrous metal, the plastic and so on many kinds of material thin plate, the strip, the coil material carries on the blanking, the punching, riveting, the molding, the shear, the bending, the fracture, shrinks the mouth, the stretch, the levelling equal technology.

6) Sorting& Packaging: Manual 100% visual inspection. Vacuum packaging bag can be used after passing the inspection to effectively avoid scratches on the product surface.

Q1: ARE YOU A FACTORY OR A TRADING COMPANY?

A1: We are professional manufacturer of High-voltage Current-limiting Fuse Part for over 25 years.

Q2: CAN I GET FREE SAMPLE?

A2: Yes, We are glad to offer free samples if you are a qualified and returning customer.For the new customer, samples fee will be deducted from the initial bulk order.

Q3: HOW LONG IS YOUR DELIVERY TIME?

A3: Our delivery time is 30 days after payment.

Q4: WHAT'S YOUR PAYMENT TERM?

A4:We accept TT, L/C and west union or you can pay through Alibaba.

Q5: DO YOU OFFER OEM SERVICE?

A5: Yes, OEM is welcome.