Position:Home> Product

Welding Parts for Contactors

Brand | Galaxy Tech |

Features | 1) Adopt MIYACHI automatic welding equipment, with good quality and high stability; 2) Solid welding, seamless welding, beautiful appearance; 3) High welding efficiency. |

Specification | No standard |

Certificate | TS16949 & ISO9001 |

Application | Measuring instruments |

Product Information

Devices that can quickly cut off AC and DC main circuits and circuits that can be switched on frequently and with high current control (some types up to 800 amps) are called contactors, so they are often used as motors for control purposes. For controlling electrical loads such as factory equipment, electric heaters, working machines and various power units, the contactor not only can switch on and off the circuit, but also has low voltage release protection. The contactor has a large control capacity and is suitable for frequent operation and remote control. It is one of the important components in the automatic control system.

Contactors are divided into AC contactors (voltage AC) and DC contactors (voltage DC), which are used for power, distribution and power. The contactor refers broadly to an electrical appliance that uses a coil to flow a current to generate a magnetic field in an industrial power to close the contact to achieve a controlled load.

1) High-quality brass material: Brass has good plasticity and high strength, good machinability, easy to weld, and very stable to general corrosion.

2) Silver alloy contact, containing 97% silver, has good resistance to burning and welding resistance, strong resistance to material transfer in DC switch circuit, widely used in various types of contactors, relays, circuit breakers And switches, etc.

3) Continuous stamping quality is stable, not easy to break and deform;

4) Accuracy is maintained and the dimensions are accurate;

5) Adopt automatic precision resistance welding equipment, with Japanese AMADA power supply as the main matching, high welding precision and stable quality.

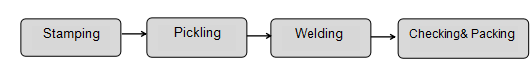

1) Stamping: 25 years of stamping production experience, continuous stamping technology, product quality stable. Our company has more than 30 press production equipment, from 10T to 110T, which are suitable for the production of various specifications. The main features of these devices are high capacity, low power consumption, and up to 2 million punches per day.

2) Pickling: A method of removing oxide scale and rust on the surface of steel by using an acid solution is a method of cleaning the surface of the metal. Common solutions include sulfuric acid, hydrochloric acid, phosphoric acid, nitric acid, chromic acid, hydrofluoric acid, and mixed acids. The most commonly used are sulfuric acid and hydrochloric acid.

3) Welding: Precision electric resistance welding is adopted, and the Japanese AMADA MIYACHI power supply is the main equipment. The welding precision is high and the welding product quality is stable.

4) Checking& Packaging: manual 100% visual inspection, sorting and packaging personnel are required to bring dust caps and finger sleeves to avoid product contamination and oxidation. After inspection, they are packed in sealed bags.

Contactor Application: Used in wind power equipment, thermal ventilation equipment, industrial electrical equipment, transmission and distribution systems and equipment, power equipment, communication, locomotive, electromechanical industry and other fields.

Packaging:

Inner plastic bag,outside carton box,bound with plastic straps,last is the pallet,all are based on the customers'.

Logistics:

Large quantity we prefer to deliver by sea, small quantity and sample orders can be by DHL, UPS, ARAMEX or other way you prefer.

Q1: IF YOU CAN NOT FIND ON OUR WEBSITE THE PRODUCT YOU NEED HOW TO DO?

A1: You can send the pictures/photos and drawings of the products you need by email , we will check if we have them. We develop new models every month, Or you can send us samples by DHL/TNT, then we can develop the new model especially for you.

Q2: CAN YOU STRICTLY FOLLOW THE TOLERANCE ON THE DRAWING AND MEET THE HIGH PRECISION?

A2: Yes, we can, we can provide high precision parts and make the parts as your drawing.

Q3: HOW SHOULD I ORDER AND MAKE PAYMENT?

A3: By T/T, for samples 100% with the order; for production, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment.

Q4: WHAT’S YOUR DELIVERY TIME?

A4:Standard parts: 7-15days

Non-standard parts: 25-30days,We will make the delivery as soon as possible with the guarantee quality.

Q5: HOW TO CUSTOM-MADE? (OEM/ODM)

A5: If you have a new product drawing or a sample, please send to us, and we can custom-made the hardware as your required. We will also provide our professional advice of the products to make the design to be more realized & maximize the performance.

Q6: HOW LONG CAN I GET REPLY AFTER SEND INQUIRY?

A6: All inquiries will be replied within 24 hours, also you may call us at any time.