Position:Home> Product

C11000 Copper Composit Busbar

| Material | C11000 Copper |

| Features | 1. Firmly & seamlessly welded with smooth appearance 2. Perform excellent thermal conductivity, ductility and corrosion resistance, and good weldability 3. Easy installation, accurate measurement and stable operation 4.Outstanding endurable & long life-time 5.High temperature resistant |

| Specification | No standard |

Certificate | TS16949 & ISO9001 |

| Application | new energy vehicles, transportation, communication, photovoltaic power generation, wind power generation and other fields. |

Product Information

Busbars distribute electricity with greater ease and flexibility than some other more permanent forms of installation and distribution. Sometimes spelled bus bar or buss bar, they are often metallic strips of copper, brass, or aluminum that both ground and conduct electricity.

Different coating materials provide different conductivity limits and variations in the length of a product’s useful life. Busbars can also come in a multitude of shapes and sizes which affect the ampacity of the product. The word ampacity refers to the maximum amount of electric current a conductor can carry before sustaining critical levels of deterioration.

1. Reduced facility costs because less construction labor means installation is less expensive and there are no costly changes and outside labor costs for electrical specialists.

2. Faster installation because building projects are up and running faster plus the ability to add, remove or relocate power easily and quickly with no downtime.

3. Flexibility for the future because some plug-in units can be disconnected and reconnected without de-energizing, require no routine maintenance and are faster and less costly for expansion or remodeling.

4. Environmentally friendly because busbars often require fewer installation materials and plug-in outlets are reusable and re-locatable.

Recent advancements to the structural integrity of busbar systems have proven changing the shape of the copper busbar greatly improves the efficiency, exposing more of the copper surface area and increasing a balanced electrical flow while decreasing its ampacity.

1 .Wire drawing:After wire drawing ,our welding components for composit busbar present metallic appearance.Its metallic looks an advanced andsharp impression.

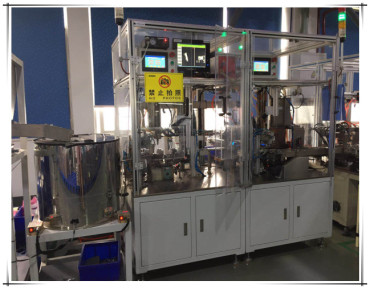

2.Stamping:Our company has more than 30 sets of high-speed precision punching equipments, from 10T to 110T, which is applicable to the production of various specifications of products.The main features of these equipment are large capacity, low power consumption, stamping times per day up to 2 million times.

3.Clearning:The four-groove ultrasonic gas-phase cleaning machine is suitable for the precision workpiece with high cleanliness. Two ultrasonic grooves can be divided into fine cleaning and rough cleaning, which can achieve higher cleaning quality and continuous cleaning in large quantities.

4.Welding:We are specialized in resistance welding, laser welding technology ,providing high-quality of welding components for laminated busbar.

5.Plating:The laminated busbar can be plated with Tin, Nickel, Silver, etc.

6.Riveting: Automatic riveting equipment with high riveting accuracy.

7.Checking& Packing: 100% manual inspection, vacuum packing bag is used to avoid scratches caused by friction between products.

Application of C11000 Copper Composit Busbar component: new energy vehicles, transportation, communication, photovoltaic power generation, wind power generation and other fields.

The C11000 Copper Composit Busbar welding components are applied in film capacitor for New energy vehicles.In general,capacitors are used in storage, motor and electric control.The composit busbar plays important part in capacitor.Soldering component of conductor material mainly use grades of C1100 cooper plate.This copper performs excellent thermal conductivity, ductility and corrosion resistance, and has good weldability.As a result,Our welding component is high temperature resistant, high reliability, long service life.laminated busbar is also called recombination busbar,a kind of multilayer composite structure busbar.It acts as a highway in distribution system.The welding component for busbar we produced is characterized by its high quality, compact-sized,easy installation,highly reliable and long service life.

Our company is located in the auto parts industry park in Xiamen city,fujian Province,China.It covers an area of about 5000 square meter.There are stamping division,welding division,research & development department, new energy division,purchasing department,quality department,material control department ,domestic department and international department.

We are specialized in precision stamping, resistance welding, laser welding, brazing TIG, argon arc and other precision welding technology .Our company introduced automatic precision silver contacts terminal welding syetem(Japan MIYACHI) .In addtion,there are glovebox welding system、automotive IC module welding system and automatic contact strip welding system.We also build precision welding joint laboratory with MADA MIYACHI.

2.Sea Freight: we will updated sea freight once we know your sea port where goods will be delivered.

Packaging:

Usually, Inner hermetic bag-- White foam box--Carton packing. We'll do according to per customers' requirements.